GOHFER, which stands for Grid Oriented Hydraulic Fracture Extension Replicator, is a planar 3-D geometry fracture simulator with a fully coupled fluid/solid transport simulator. GOHFER was developed by Dr. Bob Barree of Barree & Associates in association with Stim-Lab, a division of Core Laboratories. GOHFER has been continually refined using established formulations that have been verified in Stim-Lab’s laboratory and in the field.

A regular grid structure is used to describe the entire reservoir, similar to a reservoir simulator. The grid structure allows for vertical and lateral variations, multiple perforated intervals as well as single and bi-wing asymmetric fractures to model the most complex reservoirs. GOHFER allows modeling of multiple fracture initiation sites simultaneously and shows diversion between perforations. The grid is used for both elastic rock displacement calculations as well as a planar finite difference grid for the fluid flow solutions. Fluid composition, proppant concentration, shear, leakoff, width, pressure, viscosity and other state variables are defined at each grid block.

The in-situ stress is internally calculated from pore pressure, poroelasticity, elastic moduli and geologically consistent boundary conditions. The width solution is fully 3-D allowing shear decoupling and local displacements are controlled by local pressures and rock properties. Screenouts consider localized leakoff and proppant holdup and are not assumed to be caused by pad depletion or insufficient width. Fracture extension is based on a smoothly closing tip model and eliminates the fictitious singularity at the tip as well as the stress intensity factor.

The fracture extension and deformation model in GOHFER is based on a formulation that expects the formation to fail in shear and be essentially decoupled. Most models assume linear-elastic deformation of a fully coupled rock mass. In shales the assumption of shear is critical. Along with this GOHFER accounts for pressure dependent leakoff, transverse storage in horizontal and off-angle fracture components, and pressure dependent modulus of the bulk rock mass. All these things happen as the formation is stressed to the shear failure point. The result is higher treating pressures, smaller fracture heights, and more difficulty in placing proppant. The proppant transport model in GOHFER also includes modeling of non-uniform solid and liquid velocities, solid holdup, and variable transmissibility linked to fracture offsets and irregularities.

GOHFER allows geologic structure to be included in the modeling to simulate fracture growth in complex folded and faulted regions. Fluid and proppant injection is automatically redistributed at each timestep to model simultaneous injection into multiple perforation sets or clusters in limited-entry or horizontal well treatments. Perforation erosion and variable near-well tortuosity are modeled based on simulation of both laboratory and field studies.

GOHFER models both horizontal longitudinal and transverse fractures (multiple transverse planar fractures off of a single wellbore). GOHFER can represent the 3D stress tensor, non-orthogonal fractures, fracture reorientation, wellbore tangential stresses and breakdown conditions. It handles stress shadowing or fracture interference of multiple transverse fractures. Perforations can be selectively opened or closed throughout the simulation to model either stage by stage, multiple cluster treatments with fracture interference calculated between clusters as well as interference between stages (stage stress shadowing). Ball drop treatments may also be simulated.

GOHFER accurately models fracturing results as verified by radioactive tracer, micro-seismic and tilt-meter surveys. It is the only model that is backed by more than 20 years of laboratory research in all major areas of transport and mechanics. GOHFER includes the ability to import micro-seismic data to compare with simulation results.

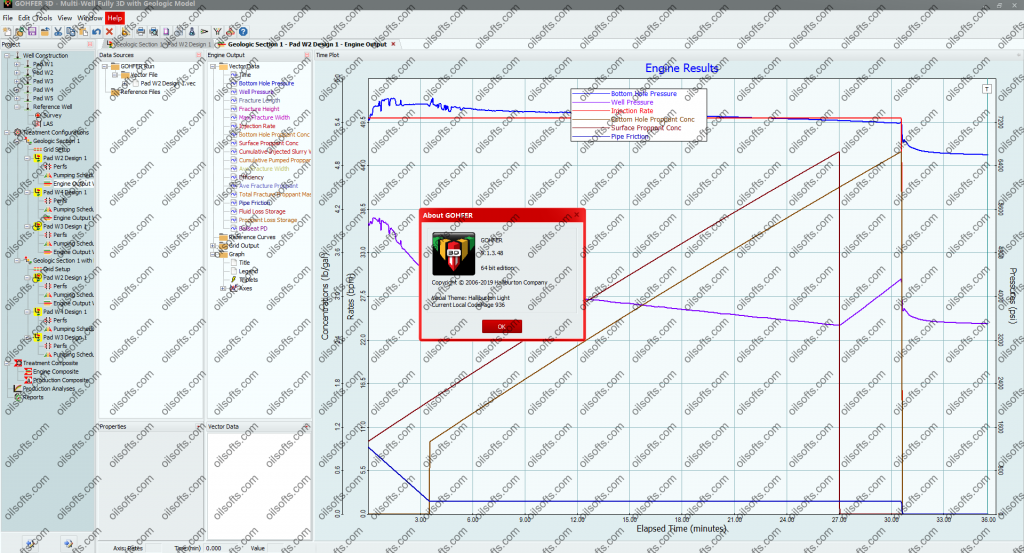

Multi-Well Fully 3D Geo-Mechanical Earth Model

GOHFERВ 3D allows for the import and modeling of multiple wells, including vertical and horizontal, in the same project/model. It accounts for the fracture stress shadow interference between each fracture and stage, on each well. Multi-layer completions, zipper-fracs, and offset depletion effects can be simulated. Allows for the import of a fully 3D geo-mechanical earth model (from Petrel GSLIB file for example). Includes the optional input of 2D surface map with reference well logs. Permits the geo-steering of laterals and engineered completions. Incorporates the full processing of log or вҖңcoreвҖқ from 3D earth model.

Log Processing

Three-dimensional fracture simulation requires data to describe reservoir properties and variations in rock properties and stress to model fracture growth and post-frac production. It is important to understand the sources of input data and the correct ways to process and interpret it. Digital well logs offer the best and most convenient method of getting data for model input. So called вҖңmechanical propertiesвҖқ logs or full-wave sonic logs are not necessary, as the required mechanical and reservoir properties can be derived from commonly available log suites.

GOHFER allows direct importing of digital log data and has a built-in log analysis package to create a more accurate lithologic description which means less tuning and fewer assumptions. The result is an in-situ stress profile that is internally calculated from pore pressure, poroelasticity, elastic moduli, and geologically consistent boundary conditions. The package includes scatter plot capability to establish linear relationships between log inputs to derive correlations. Useful “log assistants” are available to aid the user in developing a consistent geologic description.

A primary input for generation of rock mechanical properties is the compressional sonic travel time (DTC). Along with an input DTC curve several synthetic DTC curves can be generated from other available log tracks. This feature can be used to quality-check the measured DTC and to generate mechanical properties when sonic logs are not available as well as be used to help identify gas-bearing intervals. The synthetic DTC curves are very robust and correlations developed from a single input log can be used over a large area. Shear travel time (DTS) will be used if available, but is not needed to generate complete mechanical properties.

Pressure Diagnostics

Analysis of pre-frac injection/falloff tests can provide invaluable information about fracture closure stress, net extension pressure, pore pressure, reservoir flow capacity, the presence and stress state of natural fractures, leakoff magnitude and mechanism and many other parameters important to design. The correct execution and interpretation of these tests is critical to the fracture design process.

The Diagnostic toolkit contains all the tools necessary to perform injection/falloff analysis, after closure analysis and step rate injections. Injection/falloff tests can be used to determine closure pressure, net extension pressure, efficiency, the presence and stress state of natural fractures and the dominant leakoff magnitude and mechanism. Step rate injections can be used to determine pipe and near-wellbore friction, number of effective perforations open and frac extension pressure. Blowdown analysis can be used to estimate the wellbore compression at the beginning of pumping which provides a good value for the decompression at shut down. This can be used to estimate the amount of tortuosity required to match blowdown and determine a more accurate ISIP. After closure analysis can be used to define the reservoir flow capacity such as pore pressure and permeability. These methods first require the accurate identification of the reservoir transient flow regimes that occur after closure.

Production Prediction

GOHFER includes a complete production and economic analysis package that predicts production rate and volume both before and after frac. It also outputs many details regarding stimulation efficiency including all accountable damage components (to fracture conductivity), remaining effective frac conductivity, FCD, infinite-conductivity effective length, and NPV of design. GOHFER includes a filtercake deposition model related to permeability that is consistent with the expected formation flow capacity rather than fluid properties. Treatment and product costs and prices must be supplied by the user.

GOHFER uses the Stim-Lab Predict-K proppant database of more than 200 materials that have been studied extensively under actual field conditions of stress, time, and temperature. The cleanup and damage model incorporates the mechanisms identified during more than 30 years of research by StimLab (including multiphase non-Darcy flow, time dependent conductivity and stress/proppant crushing). is. The results have been verified and compared to hundreds of actual producing wells from around the world. The model has been proven to give reliable forecasts of production, if reservoir character can be defined. To our knowledge, there are no other production forecasting tools that come close to the sophistication and accuracy of GOHFER.

GOHFER runs the production analysis for the reservoir properties input to the model and for the fracture geometry, proppant distribution, proppant and fluid types that are used in the design. The model correctly handles production interference of multiple transverse fractures on horizontal wells and allows for the optimization of fracture spacing in unconventional reservoir development.

Production Analysis

The GOHFER Production Analysis module uses actual production data to analyze post-frac performance and assess stimulation effectiveness. It includes rate transient type-curve analysis, decline curve analysis, production forecasting to ultimate recovery, and flow regime identification. It can be used to determine fracture spacing and effective well spacing for horizontal wells, along with the fraction of the lateral producing